Expanded metal is produced by piercing and stretching metal plates/sheets. No material is wasted in the manufacturing process, making it economical and environmentally friendly, thus providing a good alternative to perforated metal.

Unique Advantages:

Expanded metal is known to be a versatile product greatly fit for many industries, it is fabricated when a metal sheet undergoes a process of cutting and stretching resulting in a product of mesh, it has gain popularity from its nature as being a preferred option to support textures in many fields, Materials can be diverse and vary from stainless steel expanded metal to aluminum expanded metal and many more, Since it combines functionality, robustness with aesthetics it has occupied a solid position industrially and architecturally.

Expanded metal is simple a sheet of metal that has been transformed into another type of metal with diamond shapes it is characterized with a stiff lightweight property, this procedure contributes to no waste of materials and hence it has become a sustainable and cost-effective product among other materials, it offers diverse materials, patterns and decorativeness, and expanded metal is becoming increasingly vital in construction and architecture industry.

Expanded metal greatly meets many purposes:

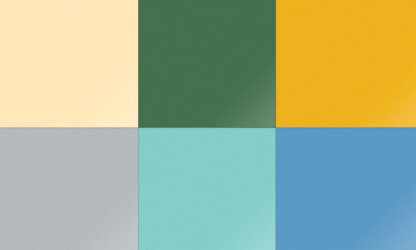

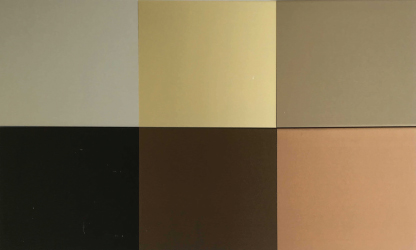

A big number of manufacturers produce expanded metal in a lot of shapes and patterns but mainly we can notice the below ones as a standard range:

Expanded metal enjoys a lot of benefits:

We should admit that both items are widely used and always in demand but we can say expanded metal is a much stronger item that has more sustainability due to its fabrication process, Compared to perforated metal, expanded metal results in zero waste, Moreover, It greatly has interconnectedness in its strands that guarantees added durability over time.

Expanded metal is winning the race now in the modern design industry, it perfectly blends privacy with transparency, and Architects utilize it for projects related to construction and architectural metal applications, it ranges from facades, and metal partitions to panels screens, and many more, we also cannot ignore its high adaptability which makes it a very desirable choice for decorative metal solutions commercially and residentially.

The price can greatly depend on many factors such as material strength, patterns complicity, and metal surface treatment. For instance:

Conclusion:

At ANB Metal we deeply understand how expanded metal is manufactured call us now to get a versatile product with a lot of applications you can used it for industrial metal applications or contemporary architectural design. Robustness, durability, and aesthetic attractiveness all these features prioritize expanded metal and expanded metal mesh over other materials making it the best match for projects functionally and aesthetically.