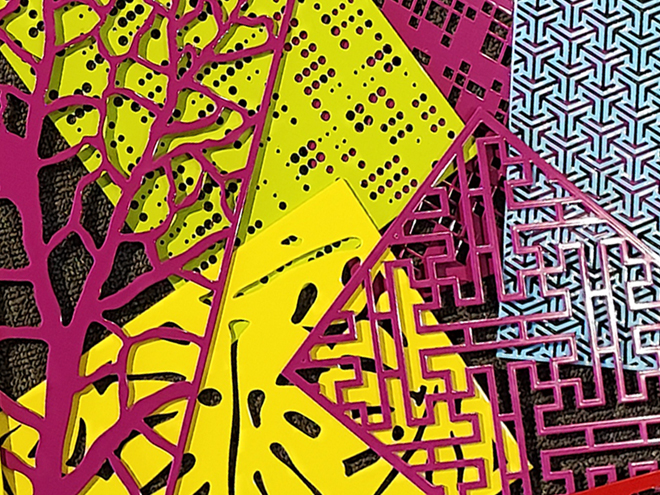

Laser-cut metals have become popular for interior and exterior applications, giving versatility and visual appeal.

We at ANB Metal provide various decorative laser-cut metal panel products in different patterns and colors to satisfy your design needs.

We are proud to announce that our architectural metal claddings, suspended ceilings, railings walls, columns, and dividers applications are all available as ready-to-install products for a unique construction experience.

In addition to our standard designs, we also offer custom laser-cutting fabrication services to create remarkable pieces that exactly match your vision.

Unlock the possibilities of laser-cut metal

Our designers can bring any idea from concept to creation – whether it is an intricate geometry, a custom logo or sign, and beyond – we can help

We utilize a collaborative design process to ensure the product meets or exceeds your expectations and sets the atmosphere.

Laser cutting is a method that uses a beam with high technology for cutting, carving, or scratching different kinds of materials with high accuracy and measurements, this technology directs intense heat from one spot to materials to create certain shapes, and the results are renowned for many qualities like smoothness, elaboration and precisions hence providing them as the best suitable solutions for many purposes.

Let's learn more about the advantages of metal laser cut

Steel: unsurprisingly, steel comes first with all its kinds including carbon steel and alloy steel when talking about laser cutting metal as it is highly on demand and affordable and provides abundance and durability at all times, it is also an ideal choice for both decorative and industrial applications without any need for other intervention

Aluminum: Aluminum comes secondly in the realm of laser cutting materials because it is known for being lightweight and more resistant to stubborn corrosion, this has made it a perfect selection for many delicate industries like automotive, architectural applications, and aerospace but we should consider that aluminum can sometimes be challenging due to its reflective nature that needs more concentration of laser power comparing to steel nature

Stainless Steel: it comes thirdly in this matter, it is renowned for its ability and strength against corrosion, stainless steel is widely utilized in laser cutting to satisfy specific needs for many industries like industrial items, medical devices, and kitchenware it is preferred because it enjoys an excellent finish quality with a variation in thickness

Many factors affect the result of a laser cut process:

Let's compare the laser cutting method to the others in the market like water jet cutting plasma cutting and mechanical cutting and find out some differences:

Do not forget to consider the following factors when selecting a laser-cut service