ANB Metal enables high-precision laser-cutting services with high-efficiency across various industrial applications through advanced laser-cutting technology, We provide laser cut aluminum, laser cut steel, laser cut stainless steel and many more metal fabrications with laser cut

We guarantee high precision and efficiency metal laser cutting for industrial applications with our laser cutting machines:

Metal Laser Cutting Advantages In Industrial Applications

High-Precision Laser Cutting for Metal Fabrication, Versatility.

High precision and accuracy of laser cutting technologies give sharp cutting and intricate designs with minimal errors, which is quite necessary where exact specifications are required. Such a high degree of accuracy is quite useful for industries requiring a perfect match and detailed work. Laser cutting serves a wide variety of metals, like aluminum, stainless steel, and steel, thereby allowing different applications in other industrial sectors.

Efficiency, Sustainability, and Customization in Laser Cutting

Laser cutting is efficient and fast; it easily handles large volumes quickly with little time needed for preparation. This improves the quality and productivity of works while keeping the lead time at a minimum for several industrial projects. Sustainable practices. It is also put into service when complex, intricate designs need to be effectuated which cannot otherwise be achieved with conventional cutting methods. Therefore, laser cutting is tailor-made for making custom industrial parts and for special applications.

Industrial Applications of Metal Laser Cutting

Let’s find out more about laser-cutting in this field:

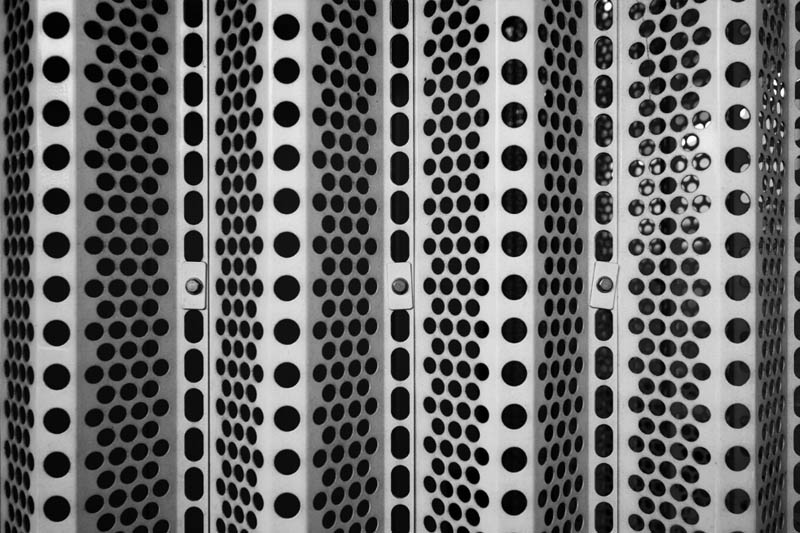

1. Construction Filed: Laser-cut metal provides functionality with aesthetic value in construction structural components, decorative screens, and custom architectural specifications.

2. Electronics World : Laser cutting is widely applied in creating complicated, precise components of electronic gadgets to meet the high performance and reliability requirements

3. Automotive: Laser cutting is always on the rise in the automotive sector for making traditional elements to any other customized parts. It enjoys top-quality engineered parts with high accuracy and precision.

4. Aerospace Industry: The aerospace sector also relies on laser cutting to create light, strong parts that come up to standard for the industry.

5. Manufacturing: Laser cutting, assures high precision and consistency in mass production when applied in the fabrication of metal parts and components.

Why ANB Metal?

ANB Metal has state-of-the-art laser cutting machines that enable the delivery of the best, with precision and efficiency for all your industrial needs.

Laser cutting is a cutting-edge technique that provides manufacturing with a precise result in many fields, this technique utilizes a focused laser beam to do many processes such as cutting, engraving, or marking materials efficiently and accurately, it is celebrated for its precision cutting technologies and widely used in diverse industries such as metal laser cutting to create decorative laser designs and many more, let's go further and learn more about the types, advantages, processes, and applications of laser cutting.

Laser cutting is a method utilized in manufacturing that includes applying a highly concentrated beam of light to the surface of metal to melt or change the integrity of material providing minimal waste with high-speed cutting.

The industrial laser systems found in machines are digitally controlled allowing for Superiority in precision and granting a high ability to create intricate shapes from metal laser cutting to detailed decorative laser designs, this method makes it a preferable choice for industrial production, architectural purposes, and custom projects.

Laser cutting can be applied to a wide range of materials:

However, we can emphasize that it is mainly effective in metal laser cutting, where high-quality and precision cuts are paramount.

Laser cutting is used in many diverse fields such as:

Laser cutting prices can greatly vary depending on several factors, such as work complexity, the material chosen, and total quantity, Laser cutting is still cost-effective for small and large production even though the initialization of the process programming costs are high and this is attributed to its precision and speed.

Presently, laser cutting is an undeniable tool to produce decorative laser designs or industrial elements, especially for those industries needing precision cutting technologies like metal laser cutting.

It offers high-speed cutting, accuracy in measurement, and energy-efficient cutting making it an ideal solution for modern manufacturing needs.