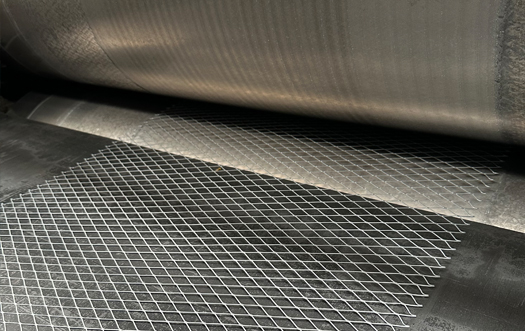

Ceylanlar Metal, a 10,000 m2 factory area, possesses state-of-the-art production equipment and independently developed machinery to manufacture over 1,000 varieties of expanded metal products. With an annual production capacity of up to 15,000 tons, we can efficiently fulfill both small and large orders from our customers in a flexible manner.

Expanded metal machines are industrial equipment used to produce expanded metal sheets typically used in applications such as architectural and industrial settings. They have production capacities based on desired eye and thickness specifications, with various mold options available. Expanded metal machines enable production without waste due to their expanding feature.

The machine flattens the standard expanded metal by straightening it with a cold roller, leaving a uniform, smooth, and flat surface on the used metal.

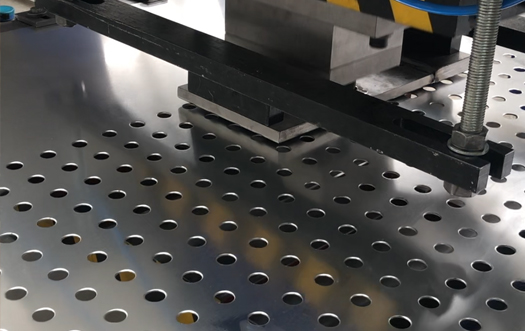

Perforation machines involve the process of perforating sheets with specific patterns to create voids. Through a driver feed mechanism and molds, different void ratios can be achieved. These machines are used in architectural and industrial applications and can produce both sheet and coil formats.

In our laser cutting machines, architectural patterns of all kinds can be cut from 0.5 mm to 10 mm according to the desired dimensions. Product precision is high in this manufacturing process, providing diversity with a wide range of products. Our machine park features high-tech CNC laser cutting, ensuring burr-free and high-quality surface processing.

Bending allows metal to be bent at different angles, enabling architectural designers to be more free and creative. As a result, mesh metal materials can be adapted for more unique and personalized designs. These metal sheets stand out for their lightness, strong structure, and aesthetic appearance, thanks to their special holes or openings. With CNC bending technology, they can be bent into different shapes and sizes.

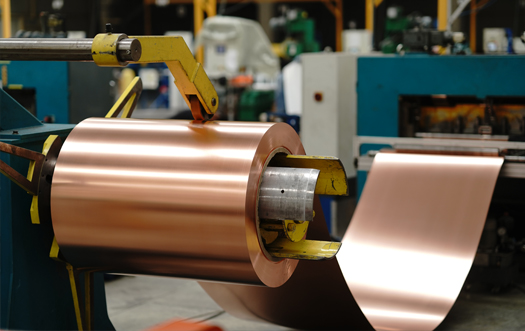

Our company has a wide range of welding capabilities. We apply the appropriate welding techniques for expanded metal mesh and perforated metals in projects with utmost precision. Welding for all types of materials including steel, galvanized steel, stainless steel, and copper is carried out within our facilities.

Various surface treatments not only enhance the appearance of expanded metal but also provide excellent corrosion resistance and anti-aging properties, thereby extending its service life. We can offer surface treatments such as hot-dip galvanizing, powder coating, and anodizing for expanded metal.