Our perforated metal panels are a marvel for both architectural and industrial purposes! These perforated sheets are meticulously crafted and offer unique design flexibility and climate control capabilities. Match form with function and elevate your projects to new dimensions.

Our stainless steel perforated sheets epitomize both strength and elegance. Specially processed for high performance, these sheets blend durability with refined style. Stainless steel provides the best corrosion resistance and a glossy surface for applications demanding excellence in metal processing processes.

We can define a perforated metal sheet and perforated metal mesh as a thin plate or sheet that is mechanically stamped or punched in a way that results in achieving a specific pattern of hole, slots, or some other shapes fabricated decoratively. In general, these kinds of holes come at equal values giving it this perforated sheet look. Perforated metal sheets can be made out of several materials like stainless, aluminum and steel. These sheets are on the way to be popular because of attractiveness provided in appearance and solid nature.

Now let's dive deeper and learn more about those metal sheets.

Unsurprisingly, the versatility of perforated metal sheets makes them suitable to be applied in a wide variety of areas within several industries, When it comes to construction, perforated plate steel is widely applied into the building architectural facades, sunscreens, and cladding for achieving functional and aesthetic purposes.

Besides this, perforated mesh sheets are on the rise as they are widely used in many applications ranging from and not limited to filter mesh, strainers, and air ventilators, we cannot deny its efficiency that provides for airflow properties. Let's continue and talk about the importance of perforated metal sheet for the automotive sector it is used at a larg-scale their to help support interior architectural elements and grilles and hence contributing to high level of functionality and diverse design wanted in the final product. Since it is a versatile material this gives it the ability to be extended to other industries for applications like agriculture for example it can play a big role in the equipment related to agro needs such as those require separators and sieves for machines. It is also applied in furniture designs as the perforated metal sheets have become more and more popular over other materials found in the market because they offer a smooth modern look and can greatly add brightness and intricateness to many styles there.

Perforated aluminum sheet and perforated steel sheets enjoy a plenty of functional and esthetic aspects that can be greatly utilized in a wide range of fields like ventilation, light proper diffusion, and sound absorption this prioritize them over another material, Moreover they can be applied for the purpose of ventilation and to provide acoustic solutions for industrial or commercial buildings blocks. As for architecture, they are mainly utilized for interior design and facades, and when it comes to industrial purposes they are tougher and lighter compared to solid panels, this can enhance their structural resistance without adding weight. They can be fabricated into diverse designs and they are ecologically friendly materials and can be recyclable easily.

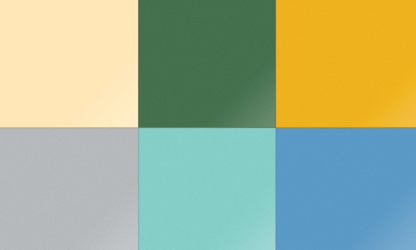

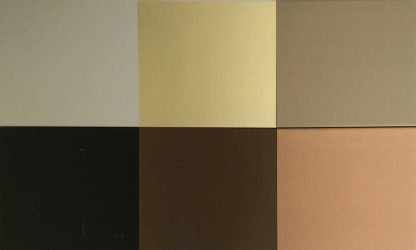

The perforated metal sheets are modern and flexible in structure and nature and can be customized to satisfy specific requirements and needs for each single projects. In addition to this, those metal sheets have a wide range of hole shapes ranging from round, square, or hexagonal shapes that give an added feature to their structure and appearance and regarding the materials a wide range can be utilized like stainless steel, aluminum, cooper and galvanized or anodized steel, selected because of their high robustness, resistance to corrosion to external factors, and durability. These sheets are preferred due to their capability in taking over light controlling, sound and airflow through premises. They also bring together unique textures and visual effects into architectural projects. They are delivered in a plenty of thicknesses and finishes offering flexibility across both interior and exterior applications as perforated metal panels

Admittedly, there are a lot of advantages coming with perforated metals, which make them common in many fields and industries. The first and most important advantage is that they permit an adequate amount of airflow and ventilation mainly in HVAC Systems, subsequently, the design of the mesh greatly put the weight at a reduction without altering the solidity of the material structure, when it comes to acoustics they improve its performance by providing a soundproofing feature for the spaces this can result in a significant decrease in noise Since the perforated metal sheets enjoy the ability to be customized into different sizes, shapes, and spacing they are preferable for several applications

In the journey of searching for perforated metal manufacturers, the best way to select the perforated sheet can usually be based on certain application of criteria that normally includes many variations like material solidity, hole designs, and finish products needed. To look deeper at this we can say materials such as stainless steel, which resist corrosion factors in the long term, could be applicable for many settings where moisture is present with high level or even used for outdoors purposes. In architecture world, the size of the hole and pattern can play an important role as it affects the aesthetic appeal as well as the relation to light and ventilation within the building. Robustness, durability, and suitability with the intended structure must also be taken into consideration each of aforementioned factors should be assessed well with an experienced supplier of those sheets.