Product quality is always our utmost concern, both for our customers and ourselves. We strive to achieve maximum customer satisfaction by offering excellent expanded metal products to our customers. We have established a comprehensive quality control system and have passed ISO 9001 and SGS certification. Our dedicated quality analysis team implements stringent quality control at every stage of production, from raw material procurement to manufacturing, from finished product packaging to final flawless delivery.

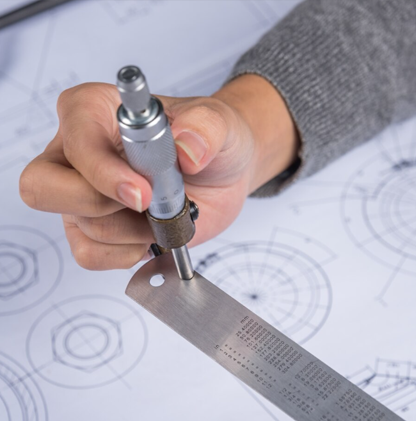

Our raw steel sheets come from renowned suppliers. Additionally, a quality inspector will ensure that the received raw materials meet and even exceed the relevant quality standards and requirements by testing their chemical composition, dimensions, and other pertinent factors. We have an independent laboratory that conducts chemical composite analysis, mesh opening tests, and product performance tests to ensure that our products adhere to manufacturing tolerances and possess the best load-bearing capacity and corrosion resistance. Furthermore, we can provide you with relevant test reports to assure you of the suitability of our products for your specific applications.

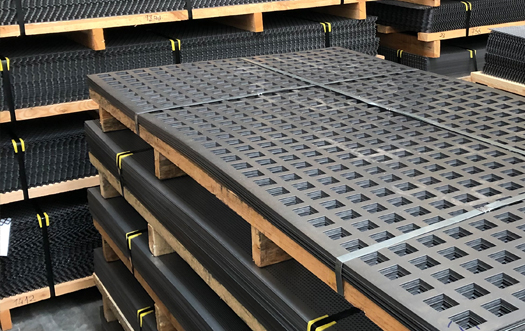

To ensure that products remain undamaged during transportation, we use waterproof, moisture-resistant, and shatterproof materials for packaging, considering the chemical and physical properties of the products. Additionally, we can provide customized packaging tailored to the specific requirements of each customer to meet their individual needs.

Our design and R&D teams are dedicated to improving product quality and developing new products, aiming to provide the best service to customers from various sectors and achieve win-win outcomes.

To ensure that all customer requirements are met before packaging, we conduct 100% product inspection on mesh opening and steel sheet thickness.