The Importance of Laser Cutting in Industrial Projects

We live in the era of technology and development, the industrial manufacturing processes have been revolutionized by many innovations among which is laser cutting, it has gained a prominent position in the industry as it offers precision cutting solutions to improve efficiency and accuracy.

Presently, industrial projects heavily rely on laser cutting to achieve coherent results in metal fabrication, manufacturing of electronics, and automotive production, it has become an essential tool in industrial application settings due to its ability to cut and shape materials into various designs and items by adopting the best material-compatible cutting technology.

Key advantages include:

- Production with Energy-Efficiency: By utilizing the laser cutting (focused laser beams technology) industries can minimize waste and make the material fully optimized in terms of usage resulting in manufacturing solutions with sustainability.

- Environmentally Friendly Laser Cutting: eco-friendliness in production practices is maintained as laser cutting technology keeps emissions at the minimum without wastage in materials.

- High Speed and Efficiency: production time is efficiently utilized since laser cutting performs at high speeds leading to a considerable reduction in costs.

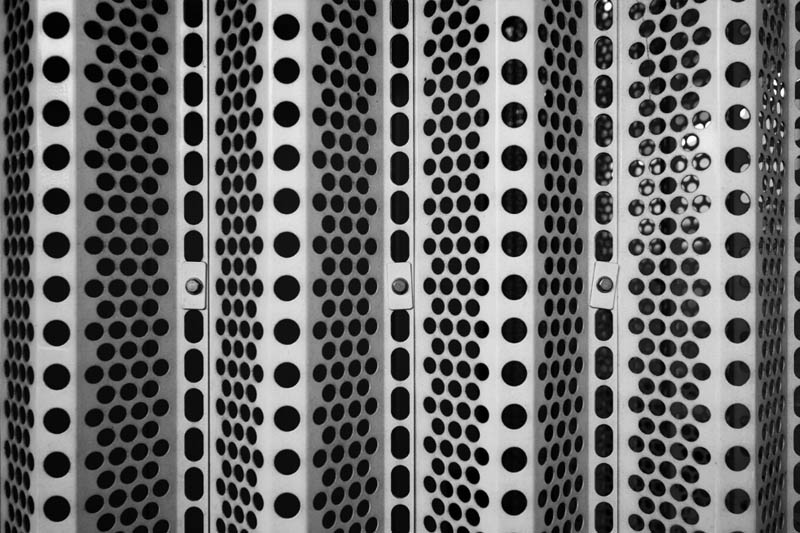

- Complex Design Production: the traditional process does not provide any intricateness in designs here the laser cut technology intervenes to perform this mission allowing for intricate cuts and more detailed patterns.

Industrial Application Areas

- Metal Fabrication: By utilizing laser cutting in industrial projects, industries can achieve adapting different types of metal like stainless steel, aluminum, and other metals with material-compatible cutting technology to guarantee that the process is done with clean cuts keeping the deformation of material at a minimum.

- Automotive Industry: Laser cutting is done by high-speed and efficient manufacturing of different parts of automotive as components of cars, body panels, and exhaust systems, this precision cutting technology ensures that those parts are precisely cut to meet exact specifications.

- Electronics and Digital Production Solutions: Digital production solutions companies rely on manufacturing modern electronics that require micro-cutting, semiconductors, circuit boards and tiny components with high delicacy, and hence laser technology is the best one to provide all of the above.

- Aerospace and Defense: The aerospace industry is a unique one that requires producing lightweight, high-strength components to fit various applications, the complex design production ability of laser cutting ensures that those intricate parts are fabricated precisely with tight tolerances.

- Construction and Architecture: The demand for material-compatible cutting technology has increased in the construction industry as this industry offers elements with solidity in structures, for the architectural world, it also provides decorative panels and customized metalwork for projects.

At ANB Metal, we know that laser cutting plays a vital role in industrial projects, we take responsibility to offer you energy-efficient production, high-speed efficiency, and complex design production capabilities.

With our laser cutting adaptability, our precision cutting technology keeps innovation alive and sustainability triggered in modern manufacturing processes.